As systems become more automated and more efficient, the introduction of grippers and end effectors has become essential.

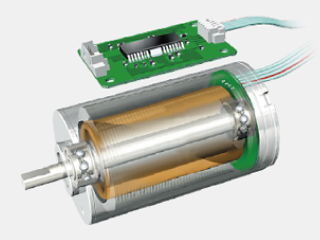

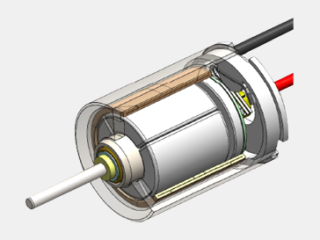

When grippers and end effectors lock up when holding an object, the current increases and they tend to generate heat. The challenge is how to suppress heat generation or cool it down immediately. Orbray's brushless motor uses a unique wire winding technology that makes it highly efficient and easy to suppress heat generation.

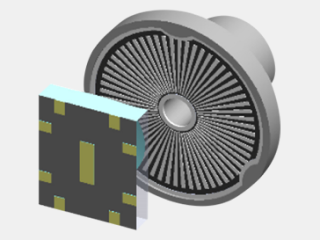

Normally, a 2-pole magnet is used in a motor, but a 4-pole motor(using a 4-pole magnet) can increase torque without changing the motor size, and can reduce the weight of the mechanism. Therefore, it is ideal for gripper applications. Orbray's motor is small and has high power, makes the machine lightweight.

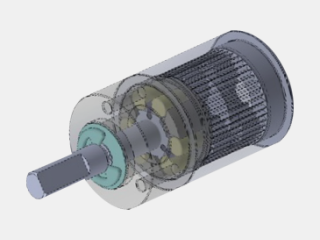

In addition, control applying torque to the gripper/end effector while keeping the rotation speed at 0 rpm, which means "locking" is required in the use. "No electricity locking system (dyNALOX)", locks the output shaft when the power is turned off, grabs objects, and never drops them.

Orbray's brushless motors are available in a wide variety of sizes: Φ7/10/12/16/17/22mm. We recommend our motors for customers who want to develop multiple sizes of gripper end effectors.

Small / High Output / High Efficiency